Rear Suspension Adjustment

To resolve alignment issues and modernize the aging rear suspension of my Datsun 280ZX, I designed and welded in a custom toe adjustment system while upgrading every major wear component. The goal was to correct geometry problems caused by subframe distortion, improve ride quality and response, and introduce tunability that the factory suspension lacked. The result is a more precise, serviceable, and high-performance rear end that transforms the way the car handles—without sacrificing reliability or home-servicability.

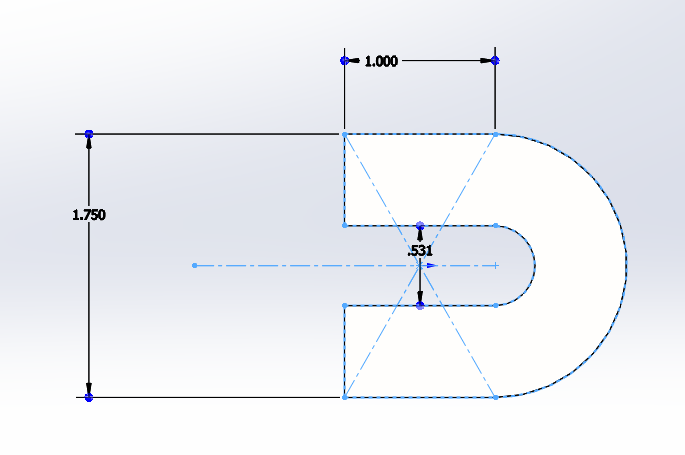

The biggest challenge was the lack of factory toe adjustment on the S130’s semi-trailing arm rear suspension. My particular chassis had noticeable static toe-in due to an old rear-end collision, which meant rapid tire wear and unpredictable handling under load. I engineered a clean, weld-in solution: laser-cut slotted brackets paired with custom eccentric washers. These allow for toe correction using standard shop tools and provide over ±0.5° of adjustment range per side. Once welded to the subframe, the system restored full control over alignment and is now easily tunable for both street and track setups.

At the same time, I rebuilt the entire rear suspension system. Every bushing was replaced with polyurethane for improved stiffness and longevity. The springs were upgraded to higher-rate units tuned for sportier handling, and the factory differential mount was swapped for a billet aluminum unit to reduce drivetrain slop and unwanted movement under throttle. The net effect is a suspension system that’s tighter, more responsive, and easier to tune—an OEM-plus upgrade that dramatically improves the feel of the car without introducing harshness.